Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing price added structure, world-class producing, and service capabilities for Excellent quality China Factory Wholesale Low Rate of Friction Loss Fiberglass Chopped Strand for Brake Pads, Together with the everlasting target of “continuous top quality improvement, customer satisfaction”, we have been sure that our products high quality is stable and trustworthy and our solutions are best-selling at your home and overseas.

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing price added structure, world-class producing, and service capabilities for China Fiberglass Chopped Strands for BMC, High Quality E-Glass Fiber Chopped Strands, We set a strict quality control system. We’ve got return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products and solutions. Be sure to feel free to contact us for further information if you have any questions. We are glad to work for every client.

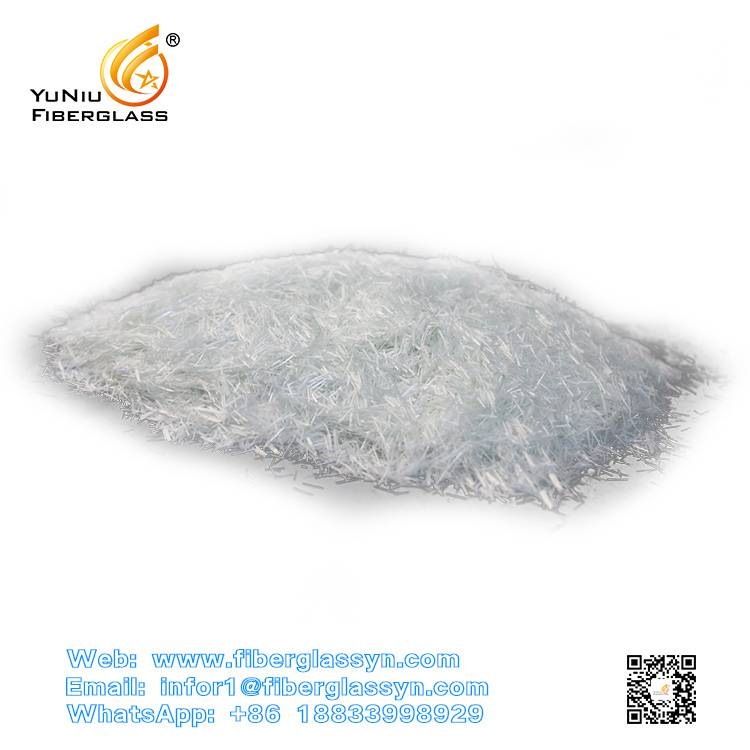

Fiberglass Chopped Strands for BMC

High Quality Fiber Glass Supplier Chopped Strands for BMC in Ecuador are compatible with unsaturated polyester, epoxy resin and phenolic resin. Suitable for the mold molding, transfer molding and injection molding technology, products of good mechanical performance, high dimensional stability and good surface finish, good water resistance, oil resistance, corrosion resistance, heat resistance, excellent electric properties, especially the arc resistance can reach about 190 s. Resin sizing agent in formula, the main ingredients with the sheet molding compound, packing, generally without thickening agent, then resin sizing agent and chopped glass fiber length (about 3 ~ 25 mm) fully mixing system. Mainly used in electrical, motor, radio, instrument, machinery manufacturing, chemical equipment, construction, transportation, defense and other departments.

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing price added structure, world-class producing, and service capabilities for Excellent quality China Factory Wholesale Low Rate of Friction Loss Fiberglass Chopped Strand for Brake Pads, Together with the everlasting target of “continuous top quality improvement, customer satisfaction”, we have been sure that our products high quality is stable and trustworthy and our solutions are best-selling at your home and overseas.

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing price added structure, world-class producing, and service capabilities for Excellent quality China Factory Wholesale Low Rate of Friction Loss Fiberglass Chopped Strand for Brake Pads, Together with the everlasting target of “continuous top quality improvement, customer satisfaction”, we have been sure that our products high quality is stable and trustworthy and our solutions are best-selling at your home and overseas.

Excellent quality China Fiberglass Chopped Strands for BMC, High Quality E-Glass Fiber Chopped Strands, We set a strict quality control system. We’ve got return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products and solutions. Be sure to feel free to contact us for further information if you have any questions. We are glad to work for every client.

-

Professional China China 300G/M2 E-Glass Woven ...

-

Best Price for China Fiberglass Chopped Strand ...

-

100% Original Factory China Rubber Filler 1000m...

-

OEM/ODM China China Fluffy Type Bulk Fiberglass...

-

Super Purchasing for China Fiber Glass Chopped ...

-

China OEM China Supplier Vinyl Coated Single Fi...